ZLYJ series plastic single screw extruder gearbox

Keywords: Hardened gear reducer, Brurick

Product number:

7

summary

Product Details

Overview

ZLYJ series single screw extruder gearbox is a special gearbox for extruder developed by our company with the introduction of the world's most advanced hard tooth surface technology. In the past ten years, it has been widely used in high and medium-grade plastic, rubber, chemical fiber extruders, exported to foreign countries, and sold in China, and has a high reputation in the industry. This series of gearboxes have the following features:

● The whole machine is beautiful in appearance, can be used for both vertical and horizontal use, and is suitable for various installation requirements.

● The gear parameters and box structure are optimized by computer; the gears are made of high-quality low-carbon alloy steel, which has been carburized, quenched, ground, and has a tooth precision of grade 6.

● The surface hardness is between 54 and 62HRC; the gear pair runs smoothly, with low noise and high transmission efficiency.

● The radial runout and end runout precision of the installation interface has reached the international level, and it can be easily connected with the barrel screw.

● The support structure of the output shaft is unique, which can effectively prolong the life of the bearings used.

● Standard parts such as bearings, oil seals, and lubricating oil pumps are all high-quality products from well-known domestic manufacturers, or imported products can be selected according to user needs.

Scope

● This series of products can be used for deceleration drive of single screw extruder with screw diameter of 30~250mm.

● The input speed of the gearbox is generally not greater than 1500r/min.

● The transmission ratio is between 6.3 and 20. The transmission ratio listed in the table is preferred, and the transmission ratio can also be adjusted according to user needs.

● The working environment temperature is -10℃~45℃. When the ambient temperature is lower than 0℃, the lubricating oil should be preheated before starting.

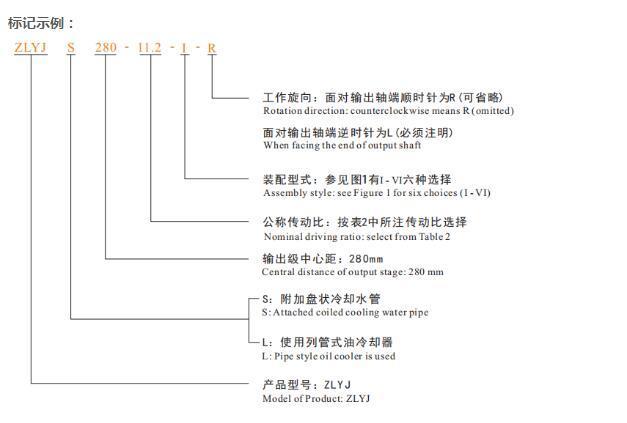

Gearbox model and mark

The code name of the gearbox includes the model, center distance of the output stage, nominal transmission ratio, assembly type and the working direction of the output shaft.

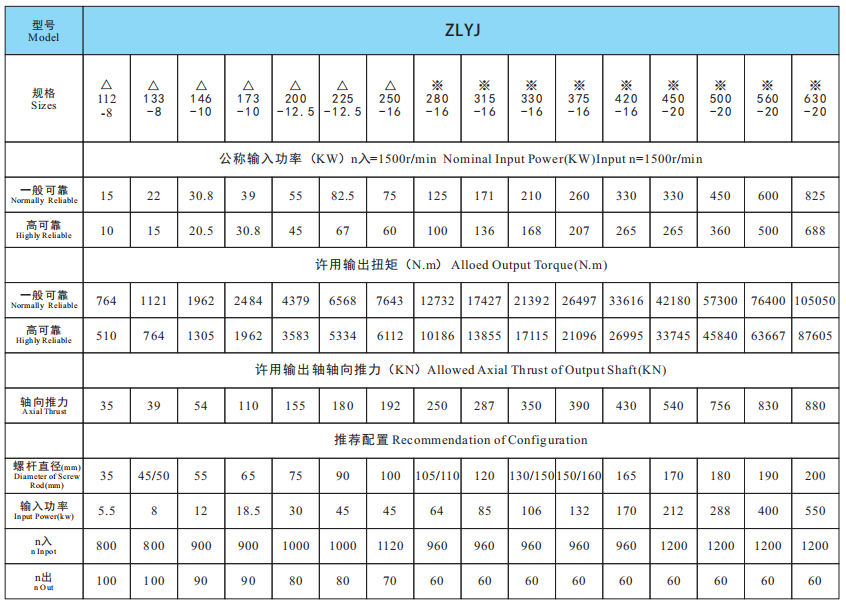

Load carrying capacity of the gearbox

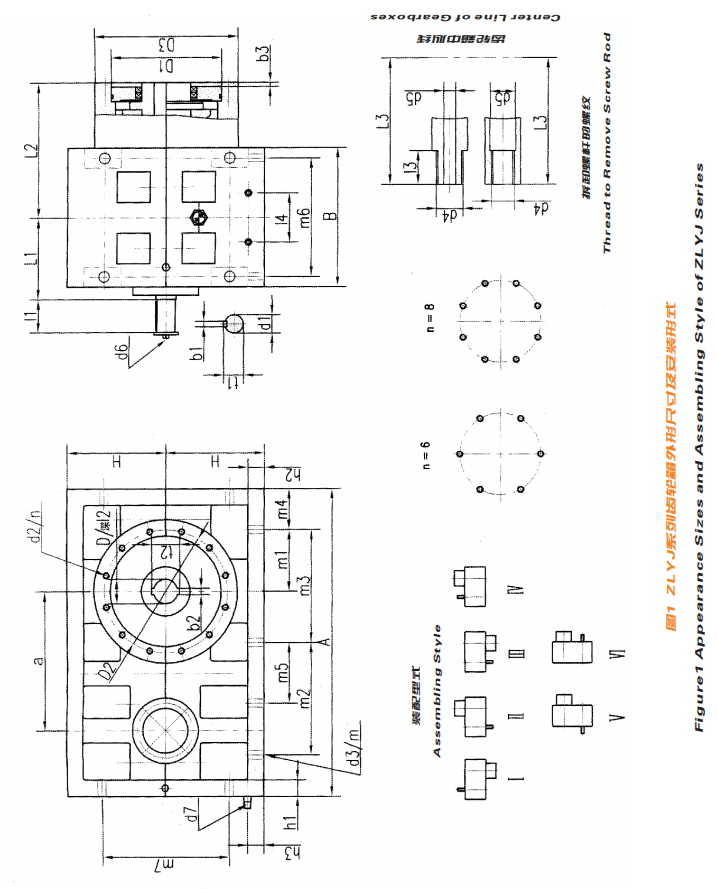

Gearbox shape and installation type

Gearbox lubrication and cooling

● Gears and bearings are lubricated by immersion oil lubrication, splash lubrication or forced lubrication as required. ZLYJ200 and above specifications are equipped with shaft end pump; ZLYJ315 and above specifications can be equipped with motor oil pump.

● All specifications can be attached with disc cooling water pipes; ZLYJ200 and above specifications can be equipped with tubular oil coolers.

● If you need additional circulating oil lubrication device or special cooling method, please contact our company.

Selection of gear box

● Check transfer power. The input power and output torque listed in the ZLYJ series have considered the working condition coefficient, which can be directly selected according to Table 2. The output torque listed in the table is the main selection basis. If the nominal transmission ratio listed in the table cannot meet the requirements, please contact our company.

● Check thermal power. ZLYJ series are selected according to Table 2 and notes.

● Check the installation connection size. If the size you need is different from the one listed in the table, please contact our company.

● Check the radial force of the shaft extension. If the input shaft adopts a connection method such as a pulley that causes additional radial force, it must be confirmed whether the radial force at the midpoint of the input shaft extension is less than 125√ T1, and T1 is the input torque. If not enough, please contact our company.

Installation and maintenance

● Use eye screws when lifting the gearbox.

● The gearbox should be protected from moisture during transportation and storage. If it is not installed within half a year after arrival, the exposed processing surface should be re-applied with anti-rust oil.

● The base on which the gear box is installed should be flat and have sufficient strength and toughness. Under the condition that the anchor bolts are evenly tightened, it should be ensured that the screw inserted into the output shaft can rotate evenly without jamming. The installation error of the coupling should not exceed its allowable deviation value, so as not to cause additional force and shorten the bearing life.

● Gearboxes have undergone strict test run inspection before delivery, and all the fingers meet the requirements, and can be put into use directly after delivery. Before use, the medium and extreme pressure gear oil N220 should be injected to the upper limit of the oil standard (using circulating lubricating oil N150). If the gearbox is equipped with a tubular tanker cooler, it must be refueled to the upper limit of the oil mark after refueling and running empty for a period of time.

● The gear box with the motor oil pump should be turned on before loading, and the motor oil pump should be run for a period of time to facilitate the full lubrication of each lubrication point.

● The oil of the gearbox should be changed after the first 300 hours of operation, and every 3000 to 4000 hours of operation thereafter, and the interval between each oil change should not exceed 18 months. When changing the oil, clean the box body, oil filter, air filter and oil drain plug first.

Key words:

MESSAGE

——

Tel

Tel

Follow us

the public

Pay attention to the public account

- Top